Kategorien: Futurex02 Rohrvermessung – Tube

Zett Mess 3D Measuring-Software

Perfect accuracy, intuitive interface and powerful features – our software gives you the opportunity to take your measurements to a new level. Optimize your processes, increase efficiency and achieve outstanding results. Rely on the expertise of ZETT MESS and revolutionize your 3D measurements.

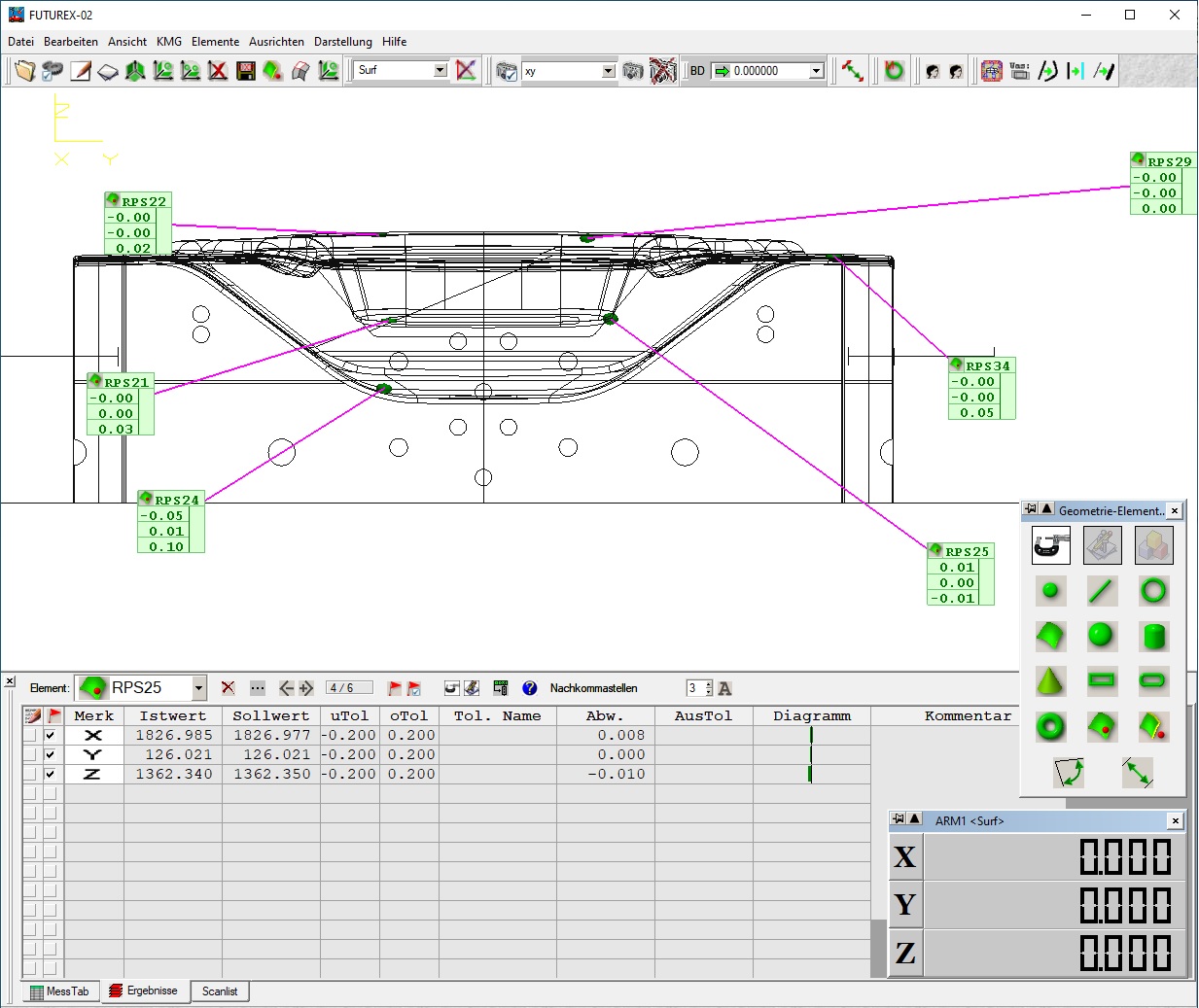

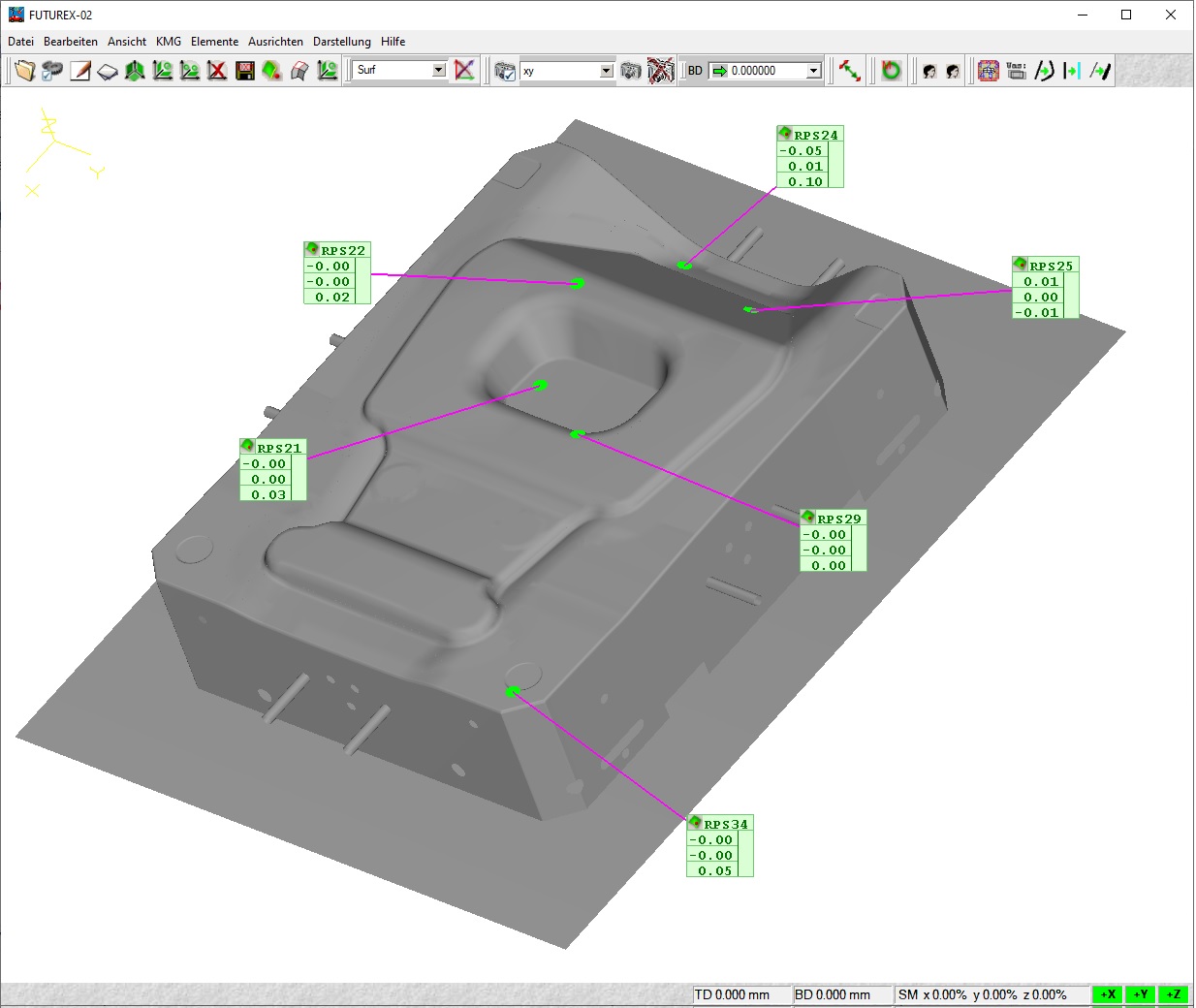

Futurex02

FUTUREX 02 is a powerful and versatile measuring software for all 3D coordinate measuring machines, regardless of the type and brand, whether manual or CNC-controlled machines. FUTUREX 02 allows you to use horizontal arm measuring machines, gantry devices as well as 6-axis measuring articulated arms or laser trackers with the same software.

FUTUREX 02 is logically structured and simple and understandable, which reduces the training time to a minimum.

Futurex02 – user interface

Futurex02 – Protocol editor

Futurex02 – CAD – data set

Characteristics

-

Common surface for geometry and area measurement

-

User-configurable interface

-

Easy to learn program operation

-

Simple creation of measurement programs

-

Integrated DMIS engine

-

Fast OpenGL graphics engine

-

Element management through our own database

-

Powerful protocol editor (WYSIWYG)

-

Support of the I++/DME standard

-

Input and output of model data via numerous software interfaces

-

Mashine-Multi-column operation in one program

-

Software maintenance contract includes 5 hours of hotline advice

Our software algorithms are of course certified by the PTB (Physikalisch-Technische Bundesanstalt).

File-formats

The following data formats are processed by FUTUREX 02: IGES, VDAFS, CATIA, Pro/E, Unigraphics, STEP, STL, Excel, ASCII, Binär, HPGL, etc.

File-formats (Export)

QUIRL, EXCEL, QS-STAT, HTML, ASCII, etc.

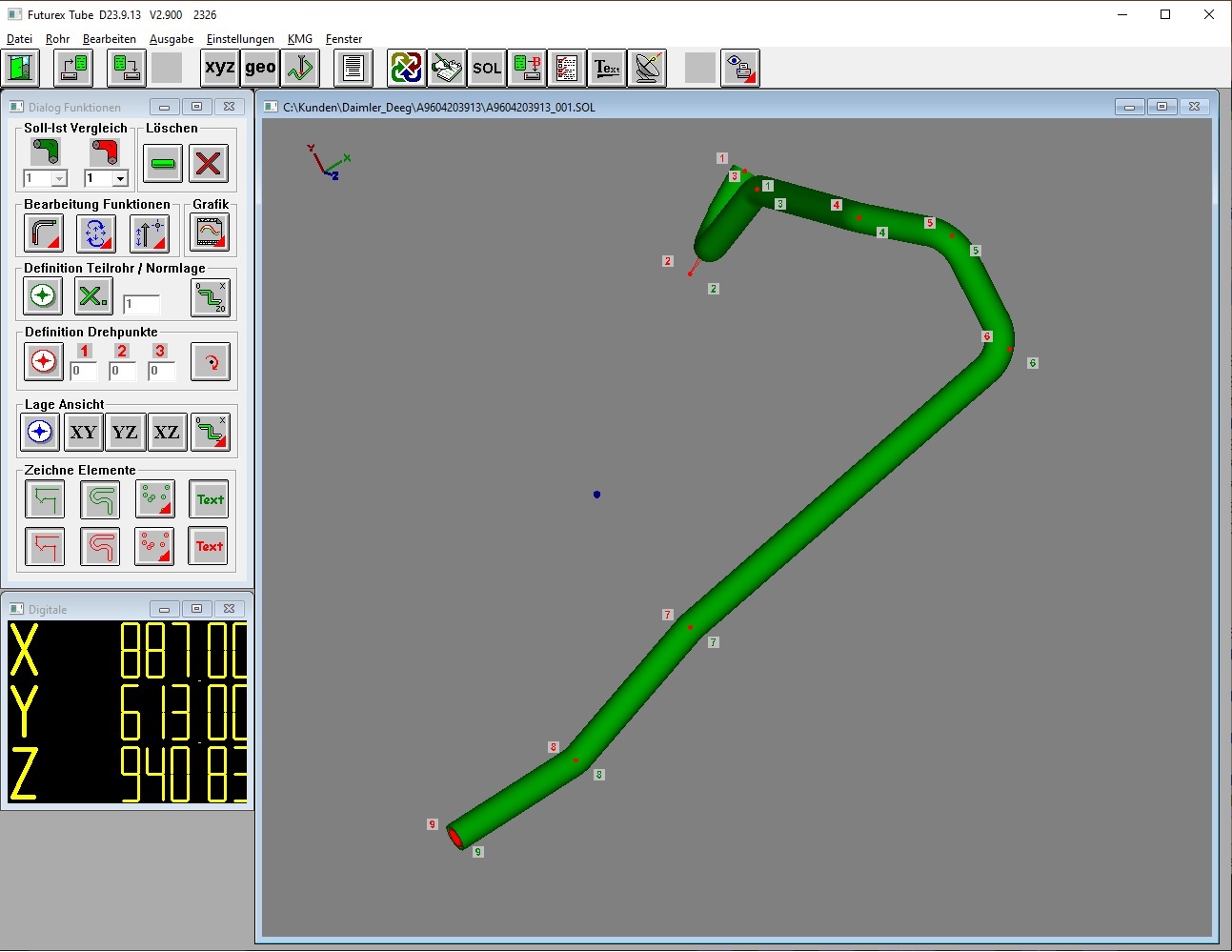

Pipe measurement program – Tube

With the FUTUREX TUBE pipe program, you are able to measure pipes in any position and shape quickly and effectively, either with a switching button or a laser pipe measuring fork. The range of functions includes, among other things, bending angle measurement, length measurement, partial pipe measurement and linking as well as pipe gauge measurement (negative form). Bending correction data for CNC tube bending machines enable convenient correction of length and bending.

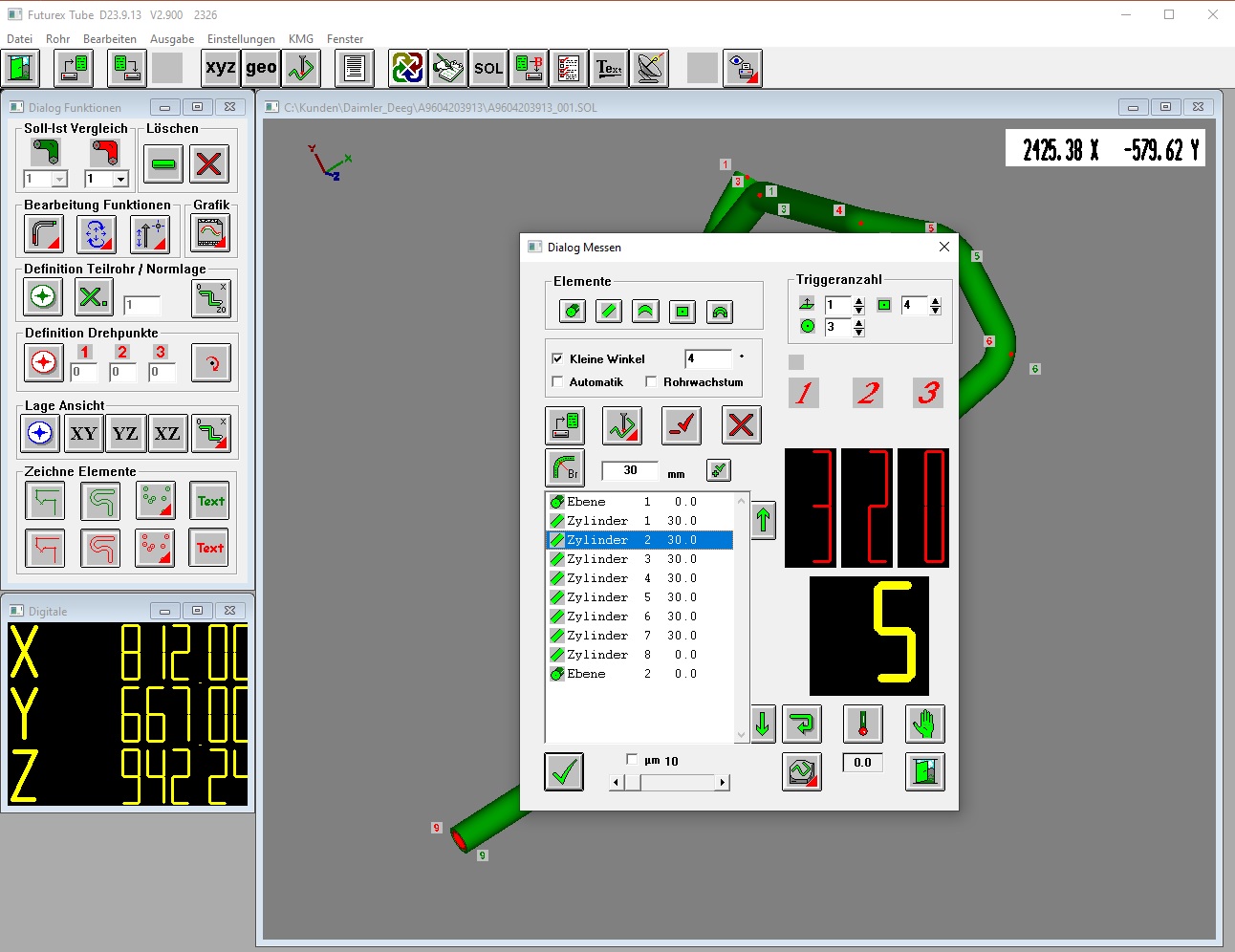

Tube user interface

Tube measuring dialog

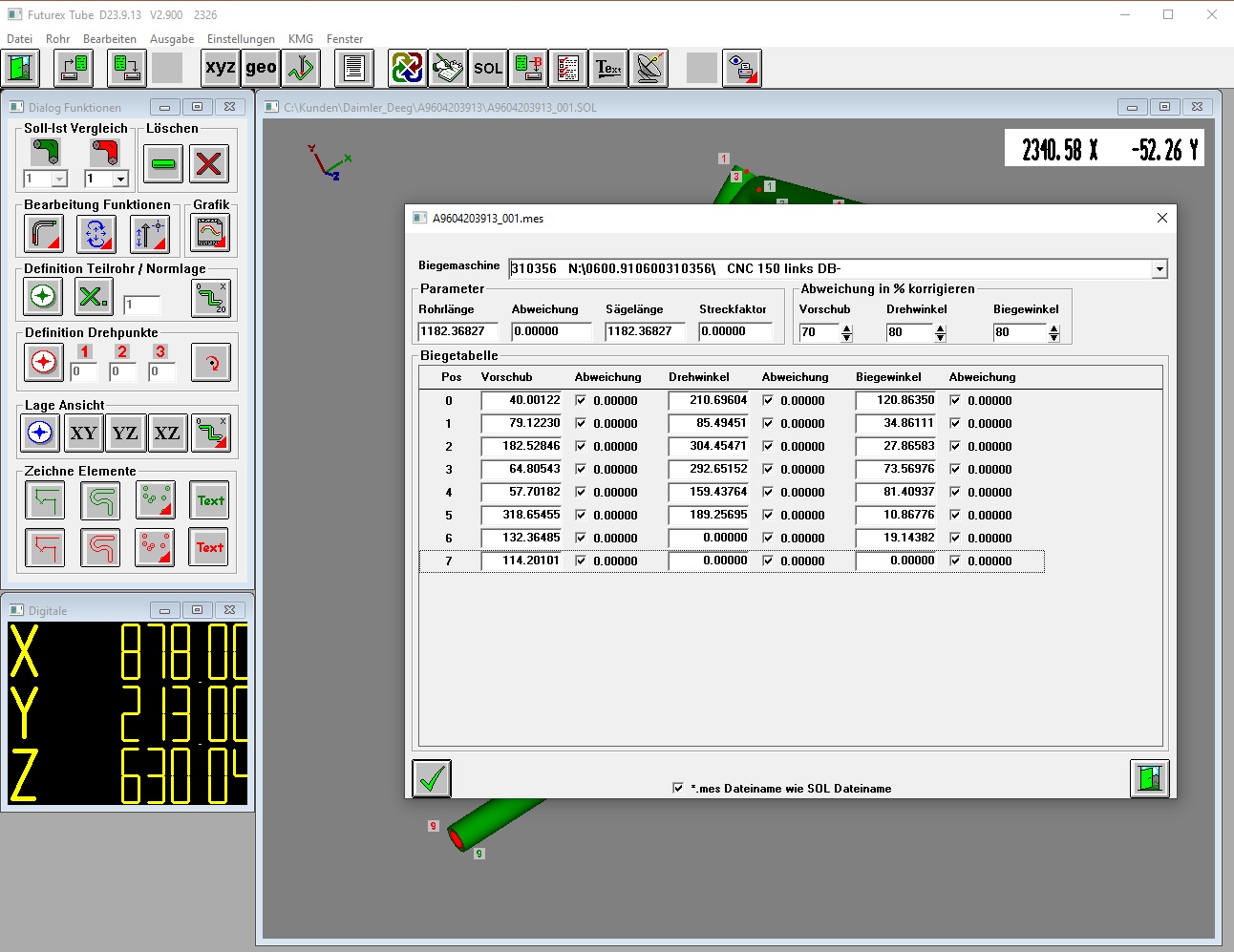

Bending parameters

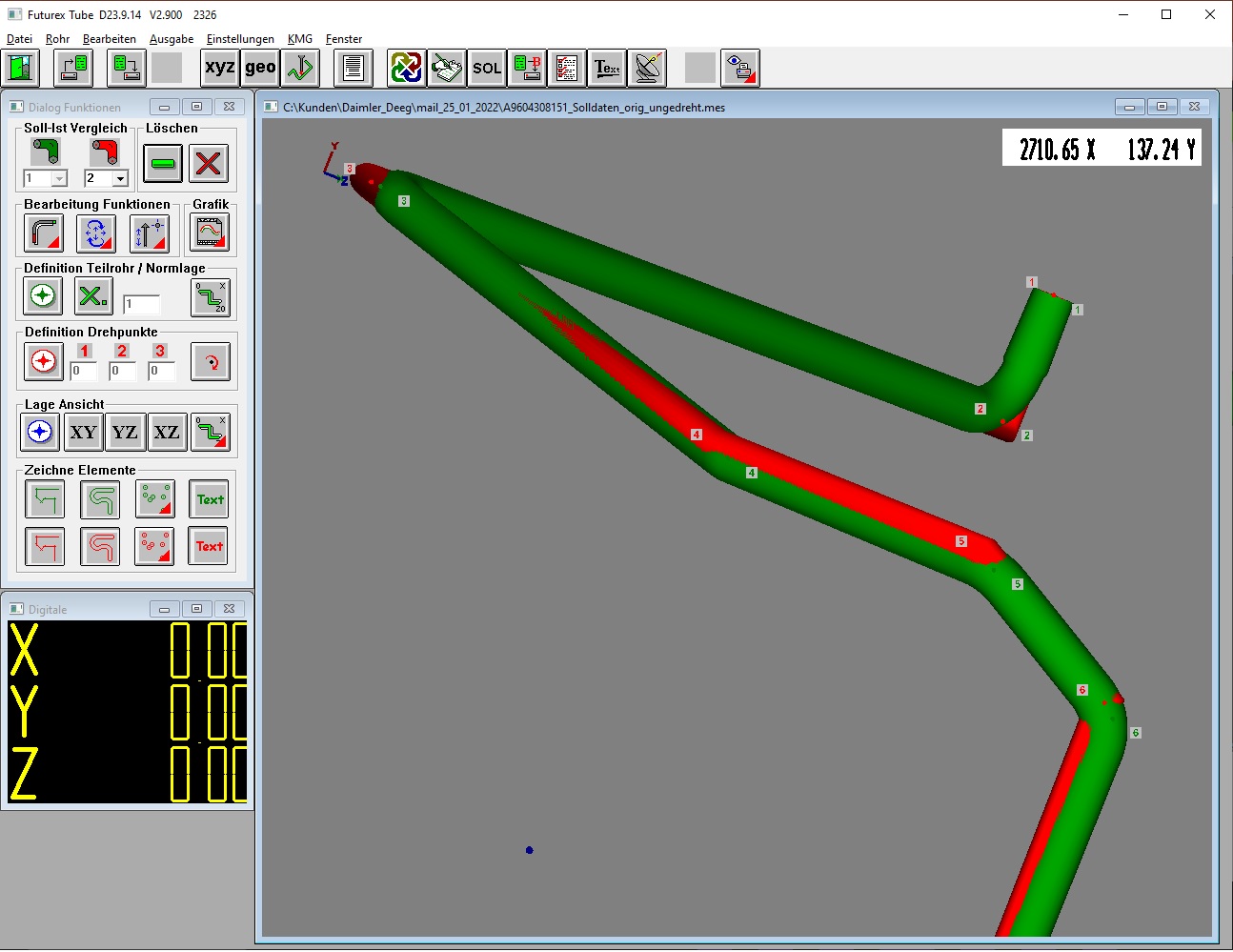

Pipe target – actual – comparison